As future winter approaches in Aston, PA, your home's gutter system faces unique challenges that require specialized preparation, and at Mighty Dog Roofing, we understand that properly installed and maintained gutters are your first line of defense against winter weather damage.

Our expertise in gutter installation throughout Aston, PA has taught us that proactive winter preparation saves homeowners thousands in potential repairs, because the right gutters don't just channel water—they protect your foundation, preserve your landscaping, and prevent ice dams from forming along your roofline. With temperatures fluctuating throughout Pennsylvania winters, your gutters need to withstand freezing conditions while maintaining optimal functionality, so let's explore how to prepare your home's drainage system for the challenging months ahead.

Winter Gutter Challenges in Aston

Aston homes near the Delaware River face unique challenges from a humid microclimate that intensifies ice dam formation, snow loads, and freeze-thaw cycles. During 35-45 annual freeze-thaw days, water expands in gutters, stressing connections. Ice dams form when attic heat escapes, causing snow to melt and refreeze at eave edges, blocking drainage and forcing water under shingles. With 20-30 inches of yearly snowfall plus additional snow deposits from nor'easters' wind patterns, Aston gutters endure substantial weight pressure.

Freezing rain creates even more difficult conditions as ice forms directly on gutters, adding significant weight when wet snow (up to 20 pounds per cubic foot) accumulates. These demands require enhanced gutter systems with higher load capacity, reinforced mounts, and strategic bracket spacing. Effective gutter installation in Aston PA includes proper sizing for melt volume, strategic downspout placement, stronger supports, and freeze-resistant materials. Mighty Dog Roofing addresses these regional challenges with comprehensive winter preparation and ice dam prevention systems designed specifically for local conditions.

Gutter Capacity Requirements for Pennsylvania Winters

Proper gutter sizing for Pennsylvania winters depends on roof dimensions and local precipitation. Professionals adjust for pitch factors—a 2,000 square foot home with 6/12 pitch actually sheds from 2,200 square feet of surface. Standard 5-inch K-style gutters handling 5,500 square feet often fail during Aston's concentrated melt-off events. Upgrading to 6-inch systems with 7,600 square foot capacity provides 38% more water flow, while 7-inch, 8-inch, or custom box gutters serve larger homes and historic properties with greater needs.

Downspout placement is equally crucial, with winter-ready systems in Aston requiring downspouts every 15 feet instead of the standard 20. Roof valleys, dormers, and transitions create concentrated flow areas needing additional capacity. Winter brings unique challenges: slower flow at near-freezing temperatures, partial snow blockage, and rapid volume during sunny post-storm days. Effective installations include overflow prevention through open-face designs, built-in channels, and auxiliary drainage paths that protect homes during extreme winter conditions.

K-Style vs. Half-Round for Winter Performance

Gutter profile choice significantly impacts winter performance for Aston properties. K-style gutters feature flat backs that mount securely to fascia boards, withstanding heavy ice loading. With approximately 30% greater capacity than same-width half-round gutters, they efficiently handle heavy meltwater flow during rapid thaws—crucial during Aston's freeze-thaw cycles. However, their angular internal design can create stress points during ice expansion.

Half-round gutters provide winter advantages despite lower capacity. Their smooth, curved interior promotes complete drainage that reduces freezing potential by limiting standing water. Their profile better accommodates ice expansion by distributing pressure evenly throughout the structure. During temperature extremes, half-rounds exhibit more uniform expansion and contraction patterns than K-style's complex geometry, reducing stress on connection points.

Winter Performance Comparison - K-Style vs. Half-Round Gutters in Aston Conditions

Feature | K-Style Gutters | Half-Round Gutters |

Capacity | 30% more water capacity at same width | Less capacity but smoother flow reducing freeze potential |

Ice Resistance | Angular design may create stress points during ice expansion | Curved profile better accommodates ice expansion |

Snow Load Capacity | Flat back provides stronger fascia mounting | Traditional bracket systems may offer less load support |

Drainage Efficiency | Corners can trap moisture that may freeze | Smooth interior promotes complete drainage |

Material Options | Available in all winter-grade materials | Limited availability in heavier gauge options |

Installation for Winter | Requires 16" bracket spacing for snow loads | May need reinforced brackets for equivalent strength |

Compatibility with Heating | Easily accommodates heat cables | May require specialized clips for heat systems |

Cost Efficiency | More affordable with comparable performance | Higher cost for equivalent winter protection |

Aesthetic Considerations | Suits contemporary Aston homes | Complements historic Aston properties |

Expansion Performance | Moderate expansion joint requirements | May require additional expansion allowance |

We offer Aston homeowners specialized winter-enhanced profiles with reinforced edges, thicker materials, and cold-weather certified systems. K-style systems need proper pitch adjustment and bracket spacing, while half-rounds require greater expansion allowance and specialized snow brackets. Aesthetically, half-rounds complement historic Aston homes, while K-style designs suit contemporary properties.

Material Selection for Durability in Freezing Conditions

Material choice significantly impacts gutter performance during Aston's winter conditions. Different materials offer varying advantages when facing freezing temperatures, heavy snow loads, and temperature fluctuations. The ideal selection balances durability, performance, and cost while ensuring your system withstands Aston's unique winter challenges.

Expansion and contraction properties are crucial during Aston's freeze-thaw cycles. Materials with high expansion coefficients stress connection points, potentially causing premature failure. Load-bearing capability determines how gutters handle ice and snow accumulation, with insufficient strength resulting in sagging or collapse under winter weight.

Winter Performance Ratings of Gutter Materials

- Aluminum - Offers balanced performance with moderate cost, light weight, and corrosion resistance. Its modest expansion coefficient (12.3 × 10^-6 in/in/°F) handles temperature changes well. For Aston winters, we recommend minimum 0.027" thickness, with 0.032" gauge for heavy snow areas.

- Copper - Provides exceptional longevity and superior load capacity for ice accumulation. Natural antimicrobial properties prevent ice-promoting organic growth. Comes with higher cost and specialized installation requirements.

- Steel - Available in galvanized and stainless options with superior strength for snow loading but increased weight and potential corrosion. In Aston's humid climate, stainless steel performs better long-term despite higher cost.

- Vinyl - Not recommended for Aston properties. Becomes brittle in extreme cold, exhibits significant expansion/contraction, and lacks load-bearing capacity for ice accumulation in Pennsylvania winters.

For optimal winter performance, we offer specialized cold-weather gutter systems with reinforced edges, thickened mounting points, and enhanced seams engineered for freeze-thaw endurance and snow slide resistance. These premium systems provide superior ice weight capacity during Aston's most challenging winter conditions.

Proper Bracket and Hanger Spacing for Snow Loads

Hardware density significantly impacts gutter performance during Aston winters, with standard 24-30 inch spacing proving inadequate. Our winter installations utilize 16-20 inch spacing based on calculations accounting for ice weight (57 pounds per cubic foot) and accumulation patterns. This prevents progressive failure from sagging to fastener movement to complete fascia separation during heavy loading. Quality installation requires heavy-duty brackets (120-150 pound capacity), proper fasteners with adequate penetration, and thorough substrate assessment for secure attachment.

Material selection enhances winter performance, with stainless steel and powder-coated aluminum brackets offering superior strength and corrosion resistance. We use specialized hardware including reinforced hangers, supplemental brackets with enhanced load distribution, and snow retention systems. For existing gutters, we offer retrofit options including strategic bracket addition, reinforcement at vulnerable points, and targeted support enhancement without complete replacement—valuable for older Aston homes where improved winter performance is essential to prevent water damage.

Hidden Hanger Systems vs. Traditional Spikes

The mounting system for your gutters dramatically affects winter performance. Hidden hangers offer clear advantages over traditional spike-and-ferrule methods in Aston's harsh winter conditions. These innovative systems evenly distribute ice and snow weight across the entire gutter back, maintaining proper shape under heavy loads and preventing the deformation commonly seen with spike systems.

Premium hidden hangers feature specialized expansion slots that accommodate the thermal movement during freeze-thaw cycles—essential in Aston's fluctuating winter temperatures. Meanwhile, traditional spike systems create stress points that frequently fail under ice loading as they loosen due to wood expansion and contraction, a process winter conditions significantly accelerate.

Key Performance Factors for Winter Mounting Systems

- Material Composition - Stainless steel offers strength for snow loads, while heavy-duty aluminum fights corrosion. Composite materials provide both strength and thermal insulation against freeze-thaw stress.

- Attachment Methodology - Screws maintain tensile strength during freeze-thaw cycles, unlike nails that loosen with temperature changes, compromising system integrity when most needed.

- Load Distribution Engineering - Hidden hangers spread weight evenly across the gutter back, while spikes create concentrated loads every 24-30 inches, affecting pitch under ice weight.

- Profile Compatibility - K-style gutters need hangers that match their angular back, while half-round systems require curved hangers for structural integrity during winter loading.

- Galvanic Compatibility - We ensure hangers and gutter materials are compatible to prevent accelerated corrosion where dissimilar metals meet in winter moisture.

For reliable winter performance in Aston's climate, we strongly recommend hidden hanger systems despite their slightly higher initial cost. When comparing long-term value, these systems deliver superior performance, reduced maintenance needs, and significantly longer system lifespan—typically 15-20 years compared to 5-7 years for traditional spike systems under identical winter conditions.

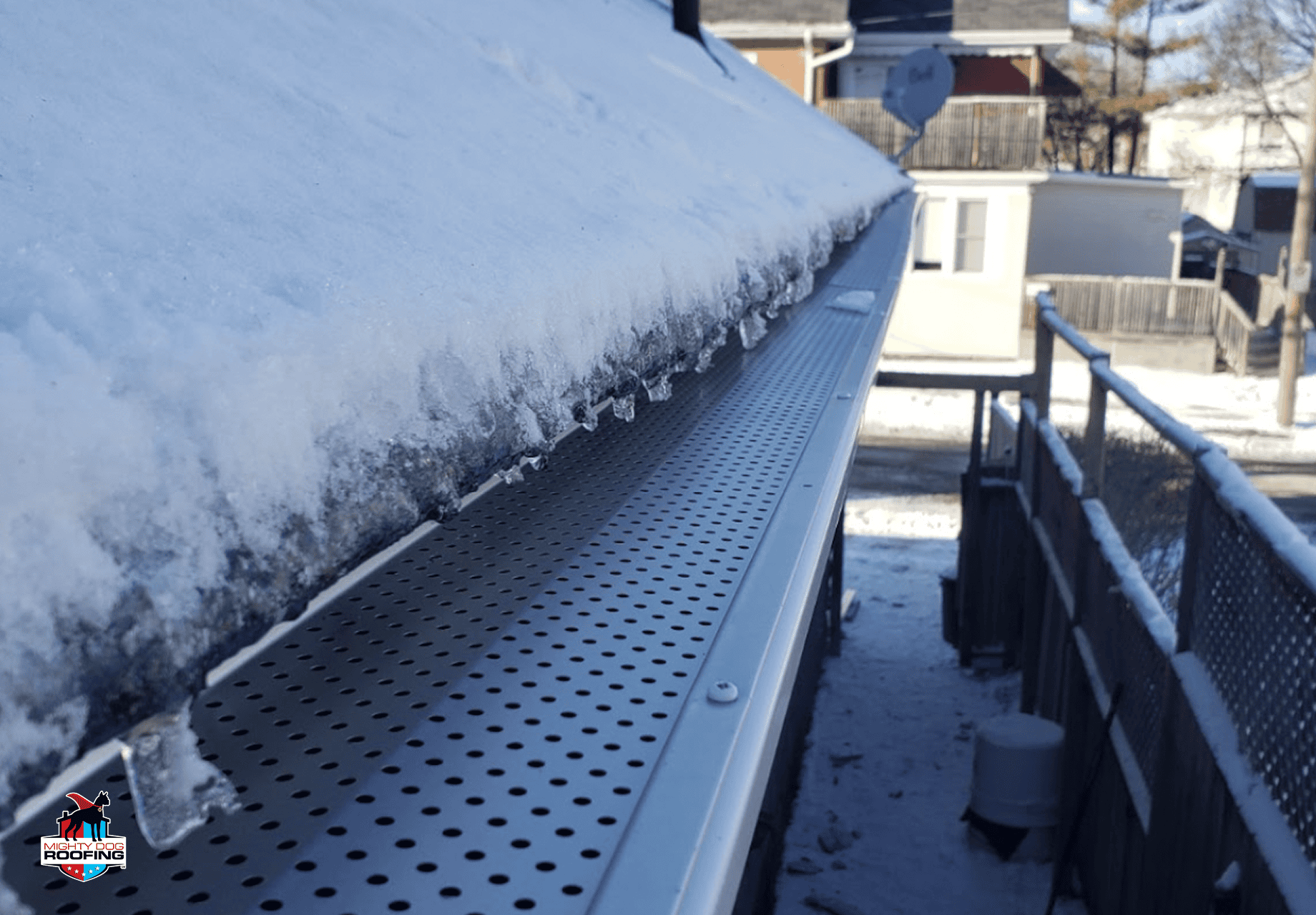

Gutter Guard Options for Winter Functionality

Leaf protection choices directly impact winter gutter function in Aston. Guard types perform differently: mesh balances debris blocking and snow buildup, with finer meshes creating snow bridges while permitting water flow; surface tension systems perform poorly when freezing changes water properties; foam inserts insulate against ice while allowing flow even when partially frozen; micro-mesh prevents snow adhesion while maintaining filtration.

Hybrid systems combine these benefits with features designed for Aston's freeze-thaw cycles. Professional installation ensures correct pitch, attachment, and heating system integration—critical for winter performance.

System maintenance affects winter reliability and value. Standard mesh needs snow clearing to prevent ice formation, while premium micro-mesh with hydrophilic coatings resists snow while maintaining flow near freezing. Foam requires pre-winter inspections, and surface tension systems need monitoring during temperature transitions.

Premium guards cost more initially (15-35% above basic), but deliver better performance with less maintenance—providing value through fewer emergency calls, extended lifespan, and water damage prevention. For Aston homes with severe winter challenges, we recommend professional-grade micro-mesh or hybrid solutions addressing freeze-thaw cycles, snow management, and integration with your complete gutter protection strategy.

Heated Gutter Solutions for Problem Areas

Heated gutters prevent ice formation proactively rather than reactively. Options include constant-wattage cables, self-regulating systems that adjust for efficiency, and safer low-voltage technologies. Installations use zigzag patterns, extend into downspouts, and protect roof edges against ice dams.

Systems are sized to match your gutters, Aston's temperatures, and typical ice patterns, providing protection without wasting energy. Control options range from manual switches to smart sensors activating only when necessary, optimizing performance while lowering costs.

Professional installation ensures safety and effectiveness. We provide proper electrical connections, secure mounting against thermal damage, and strategic placement without cold spots. We match compatible heating systems with gutter guards, as not all combinations work effectively. Maintenance includes pre-winter testing, connection checks, and performance verification.

We identify where heating delivers the best value compared to alternatives. Despite higher initial costs and modest energy use ($0.35-0.70 per linear foot monthly), these systems effectively protect vulnerable areas like north-facing sections, valleys, and spots with poor sun exposure where ice commonly forms in Aston.

Smart Technology Integration for Winter Gutter Management

Smart technology revolutionizes gutter management with temperature-sensitive heating systems that optimize performance while reducing energy use. IoT controllers monitor temperature, moisture, weather, and usage patterns to activate heating precisely when needed. Remote monitoring alerts homeowners to flow issues and blockages before damage occurs, while energy management systems cut costs by 30-40%. Advanced sensors detect potential problems before they become visible issues.

Innovative gutter materials with passive heating elements and self-clearing surfaces minimize maintenance needs. Smartphone integration enables remote system management during homeowner absence, while whole-house coordination connects gutter protection with snow removal and roof monitoring systems.

At $1,500-3,000 for typical Aston homes, these solutions provide substantial value through damage prevention, $150-200 annual savings, and elimination of emergency repairs. Mighty Dog Roofing integrates these technologies into customized solutions, delivering precisely calibrated winter protection for Aston properties. To learn more about these advanced gutter systems for your home, contact our specialists at 610-801-1462 or schedule your free inspection for a personalized assessment.